PTC 6 Flow Nozzle Meter

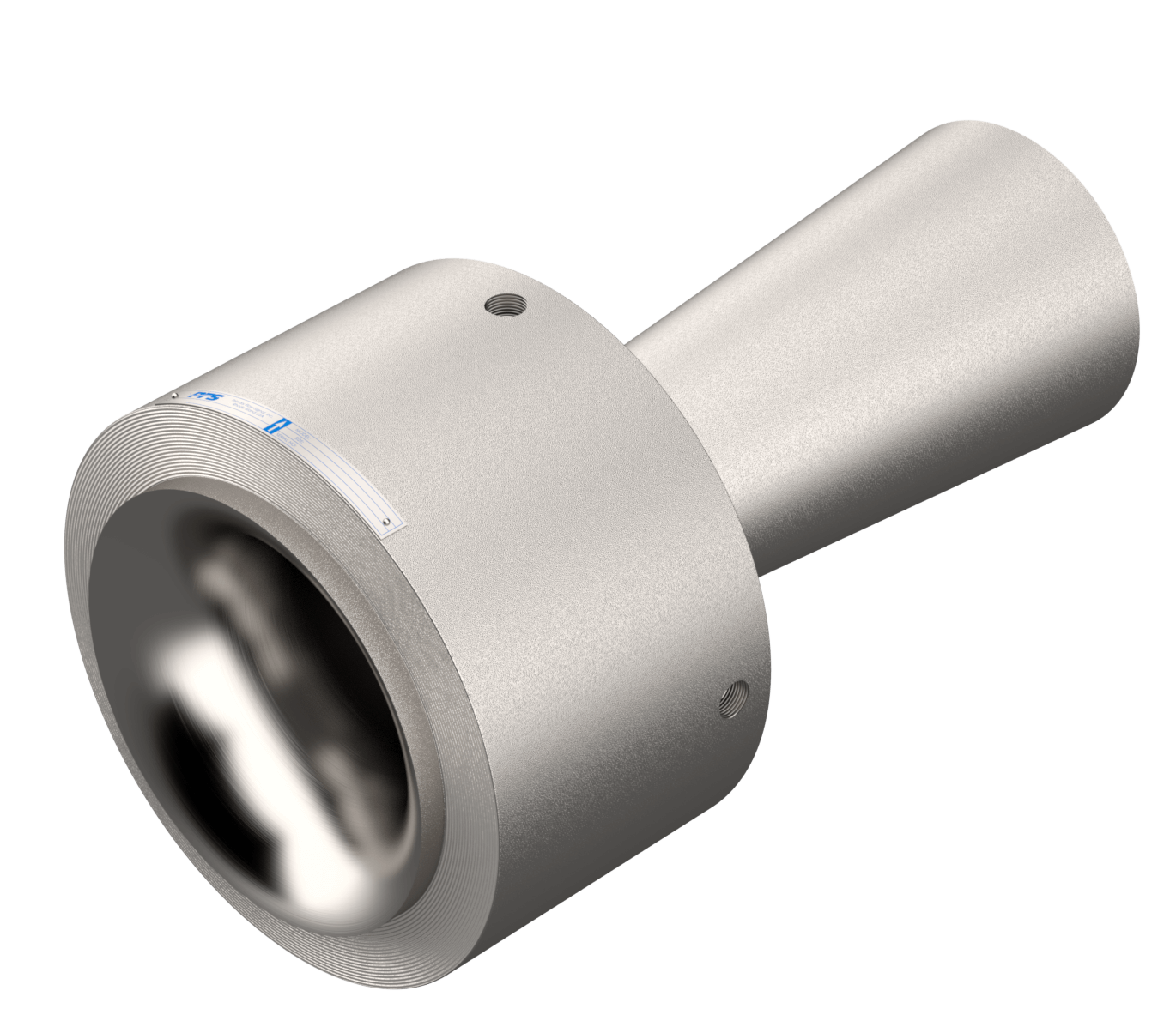

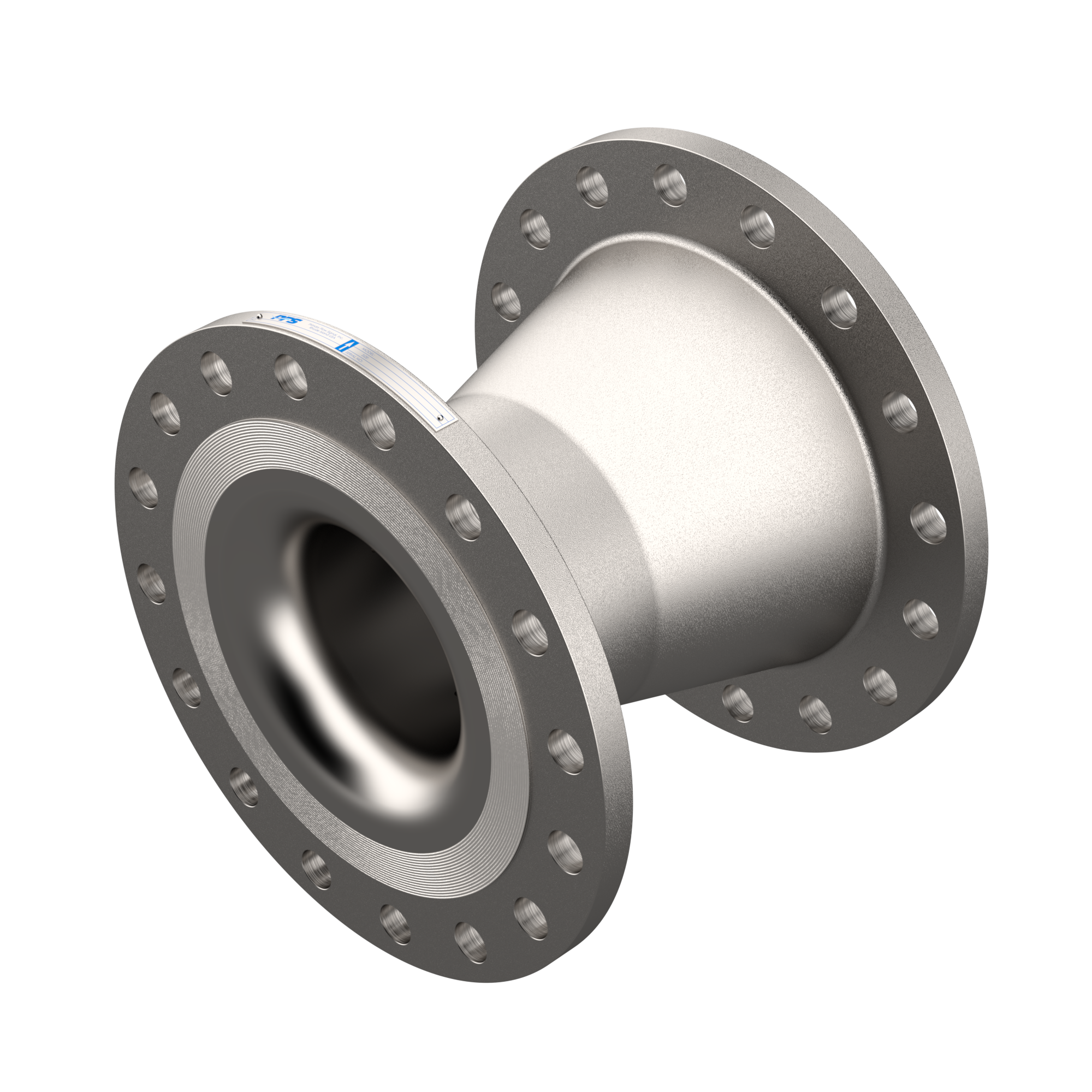

Our PTC flow nozzle meters are high-performance differential-producing flow measurement devices used as the primary element for steam turbine acceptance tests. The meters are specifically manufactured in accord with the requirements of the ASME Performance Test Code 6 (PTC6) for steam turbines.

Nozzles are available in flanged and weld-in styles, and feature interior surfaces that are precision machined for cylindricality and a hydraulically-smooth surface. For weld-in flow nozzles, a code-recommended inspection port with a removable, contoured plug is available.

ASME PTC 6 Flow Nozzle

+/- 0.25% Always Calibrated

Highest Accuracy / Repeatability

- Line size: 4 to 28 inches

- Head loss (permanent pressure loss) in % of Differential: 60% to 85% (18% to 25% with optional outlet diffuser cone), Beta Dependent

- Recommended Application, THROAT Reynolds Number: Greater than 500,000

Long Radius Flow Nozzle

+/- 2.00% Uncalibrated Uncertainty

Liquids and Gases, High-Velocity Flow

- Line size: 2 to 24 inches

- Head loss % of Differential: 30 to 85 percent, Beta Dependent

- Recommended Pipe Reynolds number: Greater than 10,000 for basic accuracy

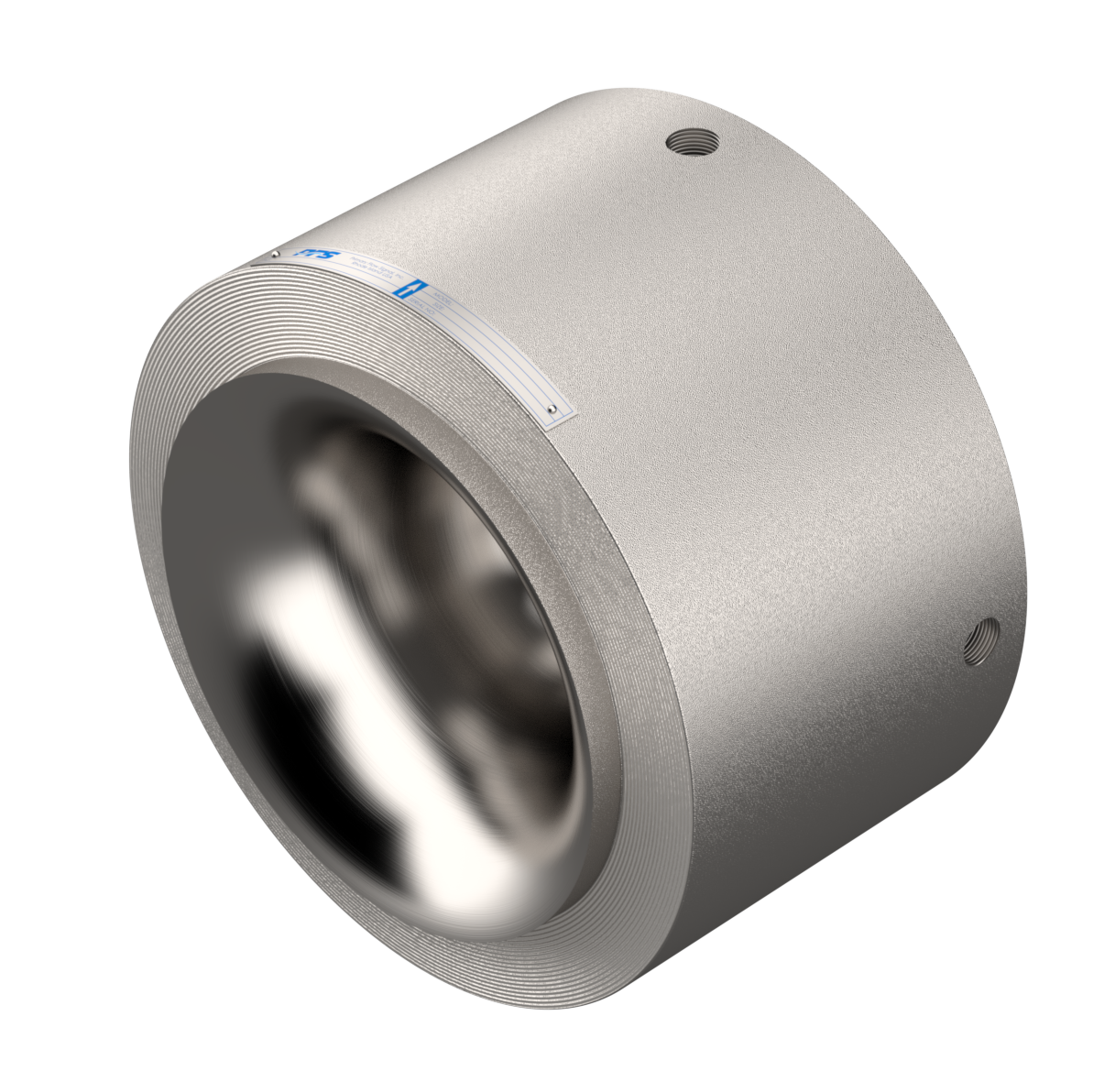

ASME PTC 19.5 Throat Tap Nozzle

+/- 0.70% Uncalibrated Uncertainty

High Accuracy

- Line size: 4 to 28 inches

- Head Loss (permanent pressure loss) in % of Differential: 60% to 85% (18% to 25% with optional outlet diffuser cone), Beta Dependent

- Recommended Application, THROAT Reynolds Number: Greater than 500,000 for basic accuracy

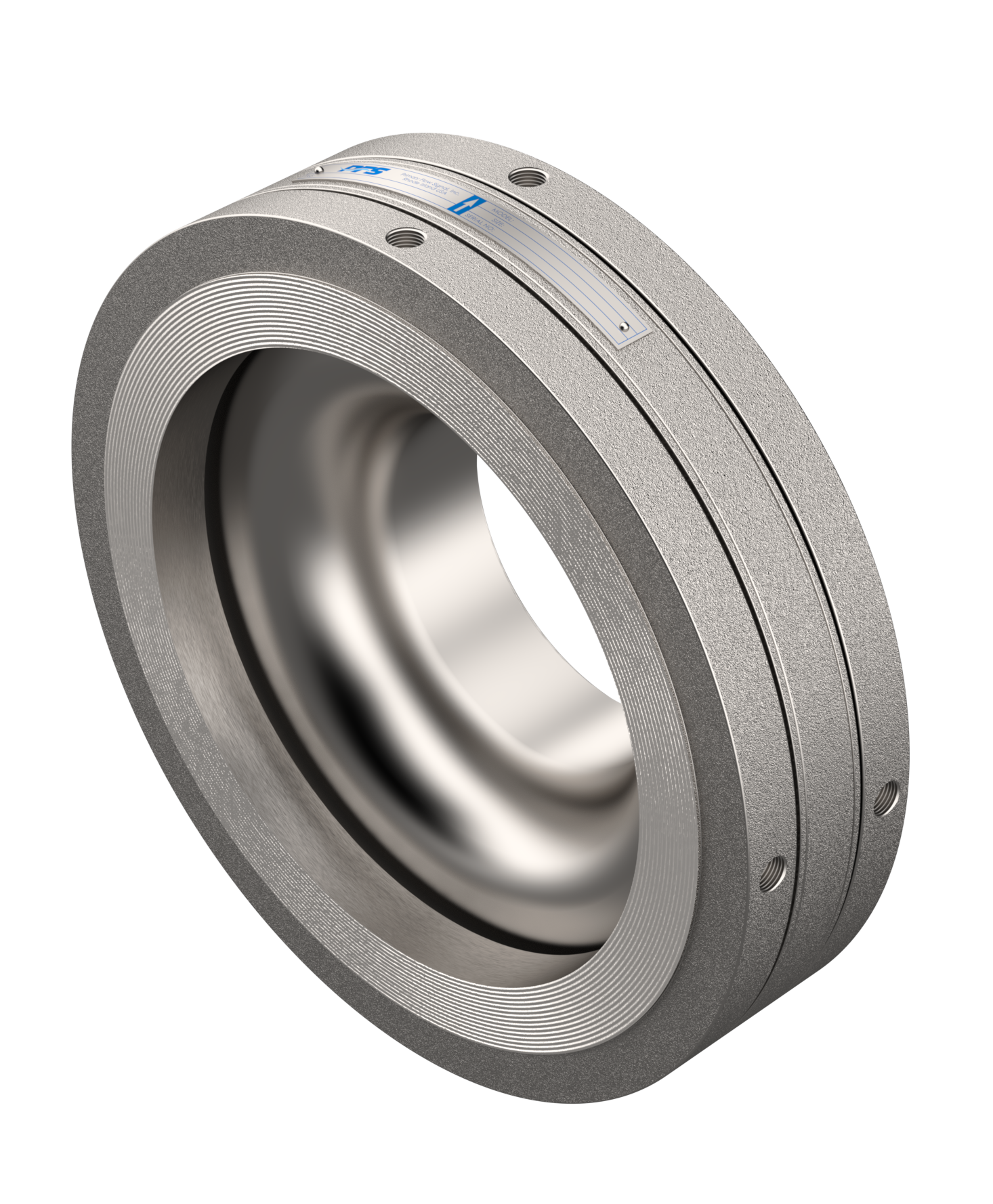

ISA 1932 Flow Nozzle

+/- 0.80% to 1.20% Uncalibrated Uncertainty

Liquids and Gases, Lower uncertainty

- Line size: 2 to 20 inches

- Head Loss % of Differential: 30 to 85, Beta Dependent

- Recommended Minimum Pipe Reynolds Number: Must be greater than 20,000 for basic accuracy

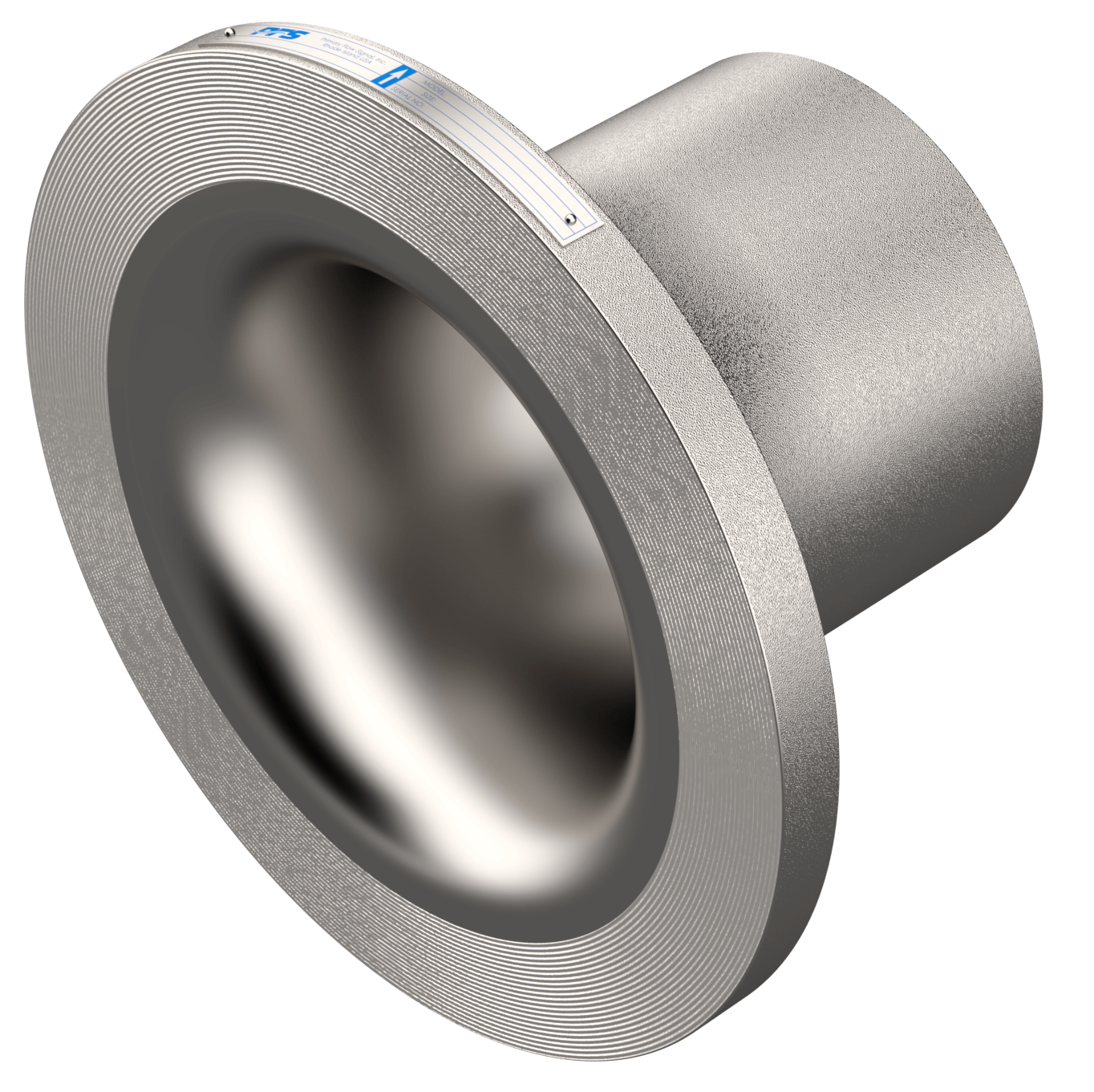

Venturi Nozzle

+/- 1.21% to 1.74% Uncalibrated Uncertainty

Liquids and Gases, Lower Loss

- Line size: 2.5 to 20 inches

- Head loss (permanent pressure loss) in % of Differential: 5% to 20%

- Recommended Pipe Reynolds Number: Greater than 150,000 for basic accuracy