Wedge Type Meter Application & Performance

By Bruce Briggs, President, Primary Flow Signal, Inc.

Wedge Meter Overview

Wedge meters were developed in the 1950s as a solution for the increasing need to accurately measure the flow of contaminated materials. During the early years of its use, the wedge meter was applied to both the municipal and industrial, oil and gas markets.

A number of new designs that expand the application opportunities of the original wedge meter including redundant pressure taps for both safety and redundancy concerns have become a mainstay for O&G refinery processing applications. The improved accuracy of today’s wedge meters based on the more accurate secondary instrumentation that is available today makes it an ideal meter for a wide range of harsh and contaminated conditions.

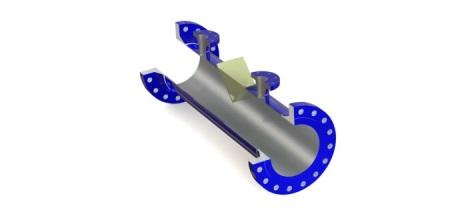

PFS Wedge Meters

The PFS wedge meter is specifically designed and manufactured to meet individual customer flow conditions. Line sizes readily available range from ½” to 24” and larger to meet your requirements.

Meters can be manufactured in various materials including Carbon Steel, Stainless Steel, Aluminum and other exotic materials as required. Installation designs are available as Flanged or Butt Weld, Threaded, Socket Weld – virtually any mating end connection required.

Wedge Meter Applications

Wedge Meters excel where others fail, accurately measuring highly viscous, rough, or solid bearing fluids and slurries, as well as gas or steam. This meter is even ideal for asphalt, tar sands, fracking fluids, spent water, sludge, cement, and other harsh industrial uses. Where required, the PFS wedge meter can be equipped with a steam jacket and multiple tapsets.

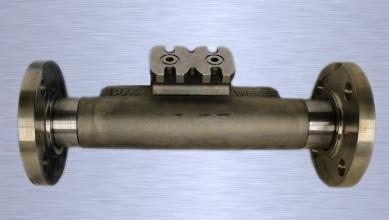

PFS developed a specially configured wedge meter that allows for the DP transmitter to be directly mounted (no impulse lines required) which has been widely used on upstream O&G applications around the world. In addition, the WedgeX is very cost-effective while providing long-term, high-accuracy performance with ease of installation and a wide range of options to suit any harsh-duty application.

PFS Wedge Meter Accuracy

- The PFS-WM provides +/- 1.0% accuracy and +/- 0.20% repeatability while measuring thick abrasive slurries, gas-infused liquids, or steam.

- Wedge Meters can be laboratory flow calibrated which results in an accuracy of +/-0.5% of rate in the installed configuration.

This differential-pressure meter consists of a cylinder with an embedded wedge, constricting the flow between sensors. It accurately handles relatively low Reynolds numbers, and the discharge coefficient is stable through the operation range. Coupling with PFS instrumentation provides a comprehensive metering solution; available instrumentation configurations include multi-variable (for gas/steam), split range, redundant service, and steam jacketed for specialized liquid asphalt and molten sulfur media.

Our new, high-accuracy, highly compact WedgeX meter integrates mounted DP transmitters to mitigate gauge line errors.

Contact Primary Flow Signal today to discuss your wedge metering needs.