ASME Flow Nozzle Uses & Applications

Flow Nozzle Meters

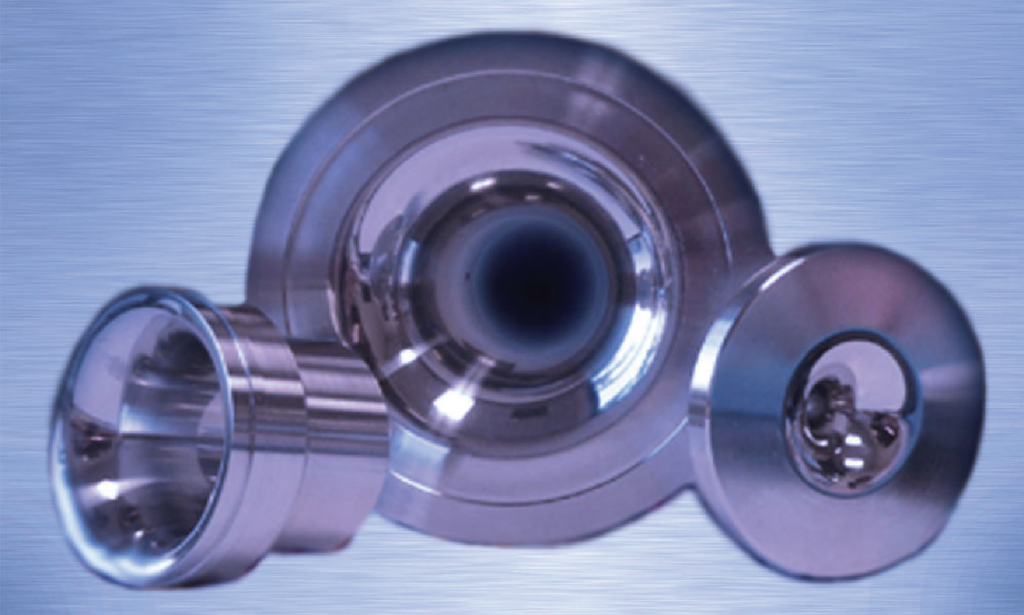

Flow nozzle meters are high-performance differential-producing flow measurement devices. Nozzles are available in flanged and weld-in styles, and feature interior surfaces that are precision machined for cylindricality and a hydraulically-smooth surface. Nozzles are used for a wide variety of applications including blower performance testing and steam flow measurement. Nozzles are particularly suitable for measuring non-viscous fluids, such as steam and other gasses. They are also suitable for some liquid applications where there is the presence of erosive and abrasive material which would eliminate the use of an orifice plate, as the bore edge of the plate would be quickly deteriorated.

Flow Nozzle Codes

A wide variety of nozzle-type devices have been applied for many years, and the most commonly applied code of construction and performance is ASME MFC-3M-2004. Other international codes, such as ISO 5167-3:2003, deal with some alternate nozzle designs such as the ISA 1932. Long-radius designs are used around the world on water, steam, power and industrial applications.

The PFS Solution

The PFS-FN Series are ASME flow nozzles manufactured in accordance with ASME MFC-3M-2004. They are typically furnished in 300 series Stainless Steel for most applications due to the high velocities and extreme environments to which they are exposed. Other materials are available for extreme temperatures and corrosive service.

The PFS-FN series is provided in various types such as

- PFS-NZF: machined with a holding flange that is flush with the inlet contour of the element

- PFS-NSFT: furnished with the downstream pressure tap machined integrally in the nozzle holding flange

- PFS-NZWI: designed for installation in the metering run by welding

- PFS-NZHR: supplied in a precision bored metering pipe where the welding of dissimilar metals is prohibited or not preferred