Orifice Flow Meter Applications & Performance

History of Differential Pressure Type Flow Meters

Over the year, a number of DP Meter types were invented and patented based on the principles of Giovanni Venturi as defined in his 1797 Treatise On The Differential Pressure Theory, the first significant invention was the Herscherl Classical Venturi Meter developed at the end of the 19th Century by Clemens Herschel; the second was the development of the Universal Venturi Tube (UVT) in the mid-1960s BY Dezsoe Halmi and the third was the development of the Halmi Venturi Tube (HVT) also by Dezsoe Halmi in the 1980s.

What is an Orifice Meter?

The orifice metering system consists of an orifice plate that has a hole or series of holes in it that are designed for specific applications such as clear liquid flow monitoring, gas and steam flow monitoring and, with specific design characteristics, designed to restrict and/or lower the upstream line pressure to a lower desired level.

Orifice Metering Systems

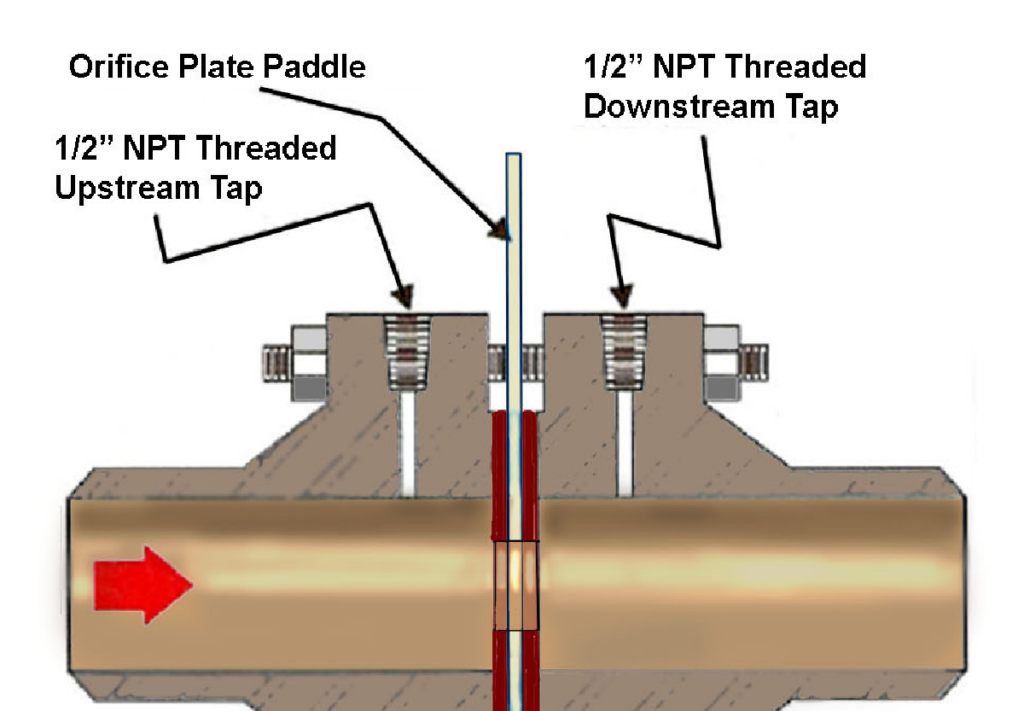

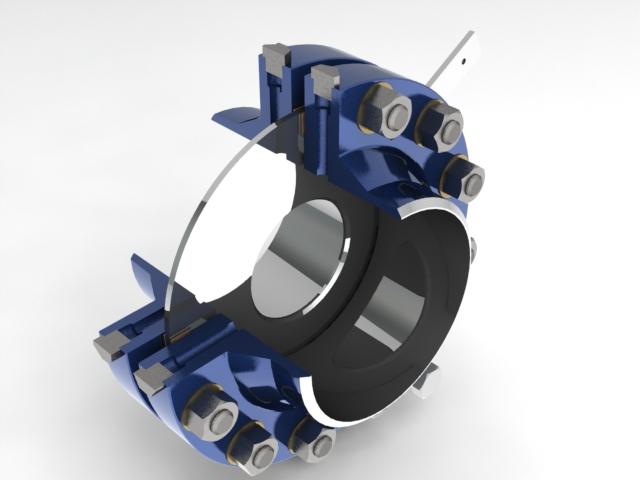

Orifice metering systems consist of the orifice plate, generally installed between two pipe flanges, and two taps that convey the high and low-pressure values that come from a pressure tap located upstream of the face of the plate and downstream from the face of the plate.

These taps can be located in a number of places as prescribed and defined by applicable codes. The taps are connected via an “impulse” line to a differential pressure sensing device such as a manometer, DP gauge or differential pressure transmitter.

Accuracy Expectations of a Properly Installed Orifice Meter

Orifice meters require some upstream and downstream straight pipe run in order for their standard accuracy to be applicable. Depending on which code and which plate design is used, the typical accuracy that can be expected from a properly installed orifice meter is +/-2.0 to +/-5.0% of rate.

Orifice Flow Design Considerations

While the differential developed across the plate is based on the type and number of holes in the plate, the basic design of an orifice meter results in high-pressure loss from the upstream line pressure to the downstream line pressure so systems which have low upstream pressures may not be ideal for using an orifice type meter.

Materials Used to Construct Orifice Meters:

Materials of construction can be whatever suits the application requirements with the basic orifice plate material being either 304 or 316 stainless steel and the flanges made of carbon steel. Gaskets are application specific including those for standard liquid service and/or high pressure and high temperature conditions.

Consult Applicable Code, Partner with Primary Flow Signal:

Consult your applicable code for upstream and downstream straight pipe run requirements for standard accuracy.

Learn more about orifice flow meters and the products we manufacture, or request information or a quote from our experts.